Welding helmets are essential safety equipment, and it is crucial to keep them clean to ensure optimal protection for the welder. Cleaning the helmet lens is the most necessary step in ensuring safety. Dirty lenses can block your vision, and in extreme cases, this can lead to serious injury.

However, cleaning your lens has a few benefits: it will reduce glare, improve visibility, and increase the lifespan of the lens. Additionally, it can help to prevent eye fatigue and other health problems.

That’s why it’s essential to use the right welding helmet lens cleaner to keep your lenses clean and protected. This article will discuss the best welding helmet lens cleaners and recommend the best overall ones. We’ll also provide tips on using them and keeping your lenses clean and protected. So why not give one a try?

| Image | Product | Detail | Price |

|---|---|---|---|

| Carson MicroBrite Plus 60x-120x LED Lighted Pocket Microscope |

| See on Amazon |

| Elikliv LCD Digital Coin Microscope |

| See on Amazon |

| AmScope M150 Series Portable Compound Microscope |

| See on Amazon |

| PalliPartners Compound Microscope for Adults & Kids |

| See on Amazon |

| Skybasic 50X-1000X Magnification WiFi Portable Handheld Microscopes |

| See on Amazon |

Understanding Welding Helmet Lenses

Before we dive into the cleaning process, let’s grasp the nuances of welding helmet lenses. There are primarily two types: passive lenses and auto-darkening lenses. The latter, with its advanced technology, adjusts the shade automatically, providing a more user-friendly experience.

Maintaining the clarity of the lens is not just about convenience; it directly correlates with safety. A dirty lens can lead to obscured vision, increasing the chances of accidents. Let’s explore the common contaminants and how they affect our welding journey.

Tools and Materials Needed

Arming ourselves with the right tools is crucial for an effective cleaning mission. A soft brush, microfiber cloths, lens cleaning solution, and compressed air are the unsung heroes in this endeavor. These tools, when used correctly, ensure that the lens is not only clean but also unharmed in the process.

| Cleaning Tools | Purpose |

|---|---|

| Microfiber cloths | Gentle cleaning without scratching the lens |

| Lens cleaning solution | Effective removal of stains and spatters |

| Compressed air | Clearing away loose debris and dust |

Preparing for Cleaning

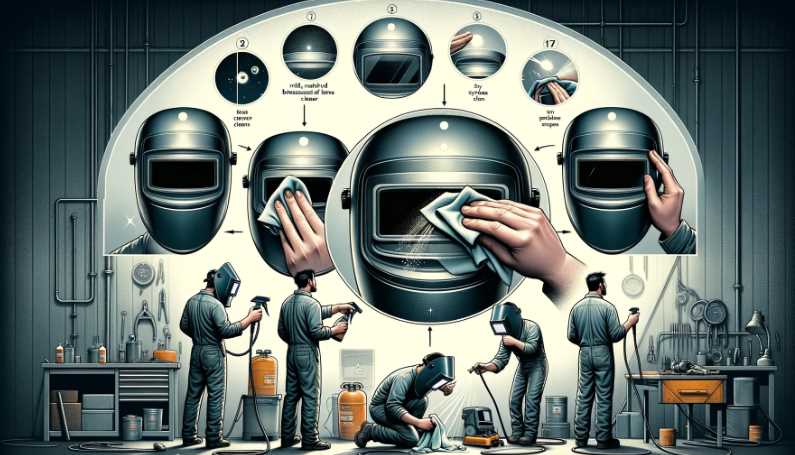

The first step in our cleaning adventure involves preparing the helmet for the cleaning ritual. Imagine a warrior gearing up for battle; similarly, we power off the welding machine, remove the helmet from our head, and carefully inspect the lens for visible debris. This preparation sets the stage for a thorough and effective cleaning process.

Cleaning Methods

With our helmet ready, we embark on the actual cleaning methods. Dry cleaning involves the use of a soft brush or air blower to remove loose particles. Picture a gentle breeze sweeping away dust, revealing the pristine lens underneath.

Wet cleaning, on the other hand, requires the application of a lens cleaning solution followed by a gentle wipe with a damp cloth. This method is akin to a refreshing rain shower, washing away the stubborn stains and ensuring a crystal-clear vision.

Let’s break down the process into actionable steps:

Dry Cleaning:

- Power off the welding machine.

- Remove the helmet from your head.

- Gently brush off loose debris using a soft brush or air blower.

Wet Cleaning:

- Apply a small amount of lens cleaning solution.

- Wipe the lens gently with a damp cloth.

- Ensure thorough drying before using the helmet again.

| Cleaning Method | Description |

|---|---|

| Dry Cleaning | Using a soft brush or air blower to remove loose particles |

| Wet Cleaning | Application of a lens cleaning solution followed by a gentle wipe |

Remember, while cleaning, avoid abrasive materials or harsh chemicals that could potentially damage the lens.

6 Necessary Safety Notes

When cleaning a welding helmet lens, it is essential to consider the precautions that must be followed. Here are six critical notes that need to be kept in mind when cleaning a welding helmet lens:

Wear a dust mask, gloves, and eye protection when cleaning the lens of a welding helmet.

Clean the lens with mild soap and water. Do not use harsh chemicals or abrasive cleaners.

Allow the helmet to air-dry before storing it.

Do not touch the lens of the welding helmet with your hands.

Do not use a hair dryer to clean the lens of a welding helmet.

Please do not use any abrasive to clean the lens; this can scratch and damage it and cause it to cloud.

6 Reasons Why Lens Gets Dirty

There are many reasons why welding helmets can get dirty, and it’s essential to know how to prevent them from becoming dull in the first place. This part outlines six reasons why welding helmets can get messy and how you can control them from happening. By reading this article, you’ll be able to keep your welding helmet clean and protected from the dirt and dust that can cause problems down the road.

Dust and other particles can get inside the helmet and become a problem. However, if dust and other particles get inside the helmet, they can block the lens and reduce visibility. This process can lead to problems with the weld and even potential injury. Keep the welding helmet clean and debris-free to prevent this from happening.

The exhaust fan on the welding helmet helps to circulate the air, but if it becomes clogged, it can cause the helmet to get very dusty. The exhaust fan is designed to suck the air out of the helmet, and when it becomes blocked, the fan can’t do its job, and the helmet gets filled with dust and debris. That is because the fan sucks in bigger particles than the openings in the fan, and that causes the particles to get stuck in the buff and move around, resulting in dust buildup on the lens.

The welding helmet may not be explicitly designed for welding, and it may not be able to handle the intense heat and exhaust fumes that come with the job. It is not effective at blocking out extreme heat and fumes. The lenses can also become scratched or foggy from the heat and chemicals.

The glare from the welding beam can make it difficult to see, leading to mistakes.

If the helmet is not correctly fitted, it can cause pressure points on the head and neck, leading to headaches, fatigue, and vision problems.

The welding helmet may not be adequately cleaned or sanitized after each use, leading to additional problems.

6 Tips to Clean Welding Helmet Lens

1. Use a soft Brush

To use a brush, start by wetting the bristles and rubbing them across the lens in a circular motion. Do not scrub the lens – give the strands a good rinse. If you find the lens too dirty to clean with the Brush, you can try using a lens cleaner.

To do this, pour the cleaner onto the Brush’s bristles and apply pressure to the strands to create a lather. Gently scrub the lens with the bristles, and rinse it off thoroughly.

2. Know the condition

Before cleaning the helmet lens, you’ll look at the helmet to review its overall condition. You don’t want to go through all the trouble of cleaning it only to miss another flaw. Doing this can prevent any potential injuries from not cleaning the lens. Here are some tips to follow when inspecting a helmet’s lens:

Look for cracks or holes in the lens. These could be signs of a more severe problem and should be fixed soon.

Check the condition of the padding and liner. If they appear worn or damaged, they should be replaced.

Check for any dirt, dust, or debris on the lens. This practice could indicate that the lens has not been cleaned in a while, and you should take care of it quickly.

Look for any sign of corrosion on the metal frame or hinges.

3. Sterilize Your Helmet Cover

It is important to disinfect your helmet lens before cleaning to prevent potential infections. Fill a spray bottle with 1 part water and three parts alcohol (preferably 70% or more). Spray the alcohol onto the lens and let it sit for at least 5 minutes or until the alcohol has evaporated. Then, use a cloth to wipe the lens clean.

There are a few different disinfectants that can disinfect the helmet lens. Some of the more popular options include:

-Soap and Water: This is the simplest and most basic option, and it works well for cleaning the lens but may not be effective against germs.

-OxiClean: This disinfectant is made from oxygen and is effective against bacteria and fungi.

-Sanitize: This disinfectant is effective against germs but may leave a residue.

-H2O2: This strong disinfectant can disinfect the lens and kill germs.

It is crucial to choose a disinfectant that is effective against germs, is safe for use on the helmet lens, and does not leave any residue.

4. Wipe the lens surface properly

To clean your helmet lens surface, clean it with a microfiber towel soaked in an anti-static UV-protectant lens cleaning solution. Make sure to apply pressure to the towel to help remove any debris. After cleaning the lens surface, rinse the towel off and dry it off completely. Finally, use a protective coating on your helmet lens if necessary.

5. Dry the Lens

Wet lenses are dangerous, as they can cause you to see double or lose focus. To dry the lens, use a bathroom towel. Hang the towel over the lens and wait until it is scorched. Then, put the helmet back on and wear it as usual.

The best way to dry the helmet lens moisture is to use the welding helmet lens dryer. This device uses heat to dry the helmet lens and can quickly and efficiently remove water. Additionally, the dryer is easy to operate and will not damage the helmet.

6. Final Checkup and Guidelines

Lastly, make sure to wear your helmet while you’re cleaning it. Of course, be careful while holding the edges, so you don’t accidentally slip and damage delicate lenses.

Clean your lens after every use for optimal visibility if you weld in a dark, dirty environment. If you weld in a clean and controlled area, you may only need to clean your lens once a week.

Here are a few other tips to keep in light while cleaning your lens:

-If your welding helmet is battery-powered or solar-powered, remove the batteries and take extra care when dealing with them

-If the welding helmet is multi lightly layered and battery-powered or solar-powered, you need to be even more gentle when removing and replacing layers.

Troubleshooting Common Issues

Our journey into the realm of cleaning welding helmet lenses might encounter some bumps along the way. Fear not, for troubleshooting common issues is an integral part of our exploration. Here, we will tackle foggy lenses, scratches, and water spots with practical solutions and insights.

Foggy Lenses:

Foggy lenses can be a persistent annoyance, hindering visibility during crucial welding tasks. The table below outlines effective strategies to address and prevent fogging:

Foggy Lenses | 1. Ensure proper ventilation in the workspace. |

| 2. Consider anti-fog coatings for the lens. | |

| 3. Use a clean, dry microfiber cloth to wipe away moisture. |

Dealing with Scratches:

While scratches may seem inevitable in a welder’s life, preventive measures can significantly reduce their occurrence. Here’s a guide to handling scratches:

| Issue | Solution |

|---|---|

| Scratched Lenses | 1. Avoid using abrasive cleaning materials. |

| 2. Regularly inspect the lens for any signs of scratches. | |

| 3. Replace scratched lenses promptly for optimal visibility. |

Handling Water Spots:

Water spots, a common aftermath of wet cleaning, can be mitigated with proper drying techniques. Here’s a quick reference to handle water spots:

| Issue | Solution |

|---|---|

| Water Spots | 1. Ensure thorough drying after wet cleaning using a clean cloth. |

| 2. Consider using compressed air to aid in the drying process. | |

| 3. Avoid excessive use of cleaning solution to minimize water spots. |

With these troubleshooting techniques, our journey becomes more resilient and our vision clearer. Tackling these common issues not only enhances the performance of our welding helmet but also contributes to a safer and more enjoyable welding experience.

Maintenance Tips for Extended Lens Life

Our exploration into the world of cleaning welding helmet lenses extends beyond the immediate task of removing spatters and stains. Incorporating effective maintenance tips is paramount to ensure a prolonged and fruitful life for your lens. Think of it as tending to a cherished garden – regular care reaps a bounty of benefits. Here are comprehensive maintenance tips accompanied by a helpful table:

- Regular Cleaning Schedule:

- Set a routine for cleaning your welding helmet lens. Depending on the intensity of your welding tasks, a weekly or bi-weekly cleaning schedule is recommended.

- Establishing a consistent habit not only keeps the lens free from contaminants but also prevents the build-up of stubborn stains over time.

- Proper Storage:

- Store your welding helmet in a dedicated and clean space, preferably in a protective carrying bag or case.

- Avoid leaving the helmet exposed to dust and debris, as this can accumulate on the lens even when not in use.

- Inspecting for Scratches:

- Regularly inspect the lens for any signs of scratches or damages.

- Address minor scratches promptly to prevent them from worsening and compromising visibility.

- Replacing Damaged Lenses:

- Don’t hesitate to replace damaged lenses. A scratched or cracked lens not only affects visibility but also compromises safety.

- Keep spare lenses on hand to ensure minimal downtime during replacements.

| Maintenance Tip | Description |

|---|---|

| Regular Cleaning Schedule | Establish a routine for cleaning to prevent the build-up of stubborn stains. |

| Proper Storage | Store the welding helmet in a dedicated and clean space, away from dust and debris. |

| Inspecting for Scratches | Regularly inspect the lens for any signs of scratches or damages. |

| Replacing Damaged Lenses | Promptly replace damaged lenses to ensure optimal visibility and safety. Keep spare lenses on hand. |

By incorporating these maintenance tips into your routine, you not only prolong the life of your welding helmet lens but also enhance its performance.

How to remove welding marks from glass?

There are a few ways to remove welding marks from glass, but the most effective is likely to be a combination of methods. You can use a scrubber to remove the surface rust and dirt, then use a glass cleaner to remove the oil and grease. Also, use a steel wool pad to remove the weld marks, followed by a glass cleaner. You can also use a polishing compound to remove the weld marks, followed by a glass cleaner. Be sure to test the mixture on a small area first to ensure it does not damage the glass.

What is a welding helmet lens?

Welding helmets come in various shapes and sizes to fit different head shapes and sizes. They also come with several lenses to allow for different viewing angles. The lens is usually made of a shatter-resistant material and is designed to protect the wearer’s eyes from the harmful effects of welding sparks and other debris.

How do welding helmet lenses work?

Welding helmets have a variety of lenses that provide different levels of protection from the harmful radiation emitted during welding. The lens typically used in welding is the half-mask lens, specifically designed to protect the eyes and mouth from exposure to harmful radiation.

The half-mask lens blocks most radiation that enters the eyes and mouth while still allowing some radiation to pass through to the eye and mouth to be used in the weld. The lens is also designed to protect the nose and mouth from directly exposing the welding arc. The half-mask lens is considered the most effective lens for welding.

What are the benefits of welding helmet lenses?

Since welding helmets are worn for various reasons, it is essential to ensure that the lens is safe and provides the user with the best possible vision. Here are the three main benefits of welding helmet lenses:

Reduced Eye Fatigue: Welding the helmet lens help to reduce eye fatigue, a common problem for those working with a lot of light and glare.

Better Vision: As mentioned earlier, welding helmet lens help to provide better vision by reducing glare and providing a clear view of the work area.

Increased Safety: An adequately fitted welding helmet lens can help to protect the user’s eyes from flying debris and metal shards.

How often should I clean my welding lens?

It is advisable to clean your lens for general welding every few weeks. Using high-quality equipment, you may only need to clean your lens every few months. Always use a quality cleaning solution and follow the manufacturer’s instructions.

How can I make my welding lenses last longer?

Welding lenses are an essential part of any welder’s equipment, and it is necessary to take care of them to ensure they last as long as possible. Here are a few tips to help you make your welding lenses last longer:

Follow the manufacturer’s instructions carefully when it comes to cleaning and maintenance.

Avoid using harsh chemicals or cleaning solutions when cleaning your welding lenses.

Make sure your welding lenses are fitted adequately before every use.

Avoid wearing your welding lenses while welding.

Store your welding lenses in a cool, dry place.

What are the best 3 Ways To Clean welding Lens??

There are a few things that you can do to clean your welding lens to ensure that you have a clear view of the work that you are doing.

Buffing Wheel

That might seem effortless and straightforward, but if you want to avoid getting a new replacement welding visor because yours has scratches, here’s what you can do. All you need is a buffing wheel and some light polishing compound. You will want to buy the mix-in-bar formula and ensure a spinning wheel is on hand.

Before you start, you will also have to check the pressure that needs to be applied to the welding helmet lens. Make sure it is not too much or too little; otherwise, polishing may not happen. As you use a welding helmet more often, the marks will no longer expose in the future. At this instant, it’s time to get a fresh, clear shielding lens.

Rubbing Mixture

In addition to using a microfiber cloth and water, you can also use a wiping compound. Car detailers usually use a rubbing combination. In particular, this rubbing compound, 3M 05973, removes scratches, dirt, oxidation, and other marks on the lens. This compound is designed to work well with every external polycarbonate.

It might look slightly costly, but you only use a small number of dribs when washing the lens, which will last a long. This is a fine-grit rubbing compound for welders who do not want to scratch their lenses. First, dab a few drops on your lens, then gently wipe with a towel or microfiber material. Next, add some more rubbing compound and rub with a soft cloth.

This will remove all dirt and grease from your lens and give it an almost new appearance. Once the rubbing mixture dries, clean it with a soft cloth to avoid leaving streaks or bleary marks behind.

Polishing Properly

With helmets, the final step is to polish them with wax or car polish. Although I use a glass cleanser at the start, this will still help, as the polish removes dirt and leaves a protective film that prevents scratches.

It also reduces fogging and ensures your lens won’t smudge and get blurry. As a final point, the polish blocks in good marks and extends the lens life, so it doesn’t need to be replaced as often. When polishing, wipe off any residue using a soft cloth in circular motions to prevent smudging.

Tip #1: use glass cleaner to remove the majority of dirt from your helmet before using a polishing agent

Tip #2: if you use paint or polish, wipe off any swirl marks to prevent a scratched lens

Tip #3: once the polish has dried, be sure to wipe off any residual to ensure you don’t have a smudged lens

Tip #4: some helmets come with a warranty, and you don’t want them to expire too soon because of scratches.

Tip #5: be sure not to put any of these products on the inside of your helmet, as they may affect your breathability/ventilation.

How to test the auto-darkening welding helmet auto-darkening lens?

Testing the auto-darkening welding helmet auto-darkening lens is simple and can be done in just a few steps. First, ensure that the lens is correctly installed on the helmet by aligning the center of the lens with the center of the helmet’s mirror. Next, adjust the lens to your desired darkness by turning the adjustment wheel on the lens’s side. Finally, use the light switch on the helmet’s side to turn on the light. The light should automatically darken as you work if everything is in working order.

What lens comes with a welding helmet?

A welding lens comes with a welding helmet to ensure a clear view of the weld area. It is essential to have a clear picture of the weld area to ensure that it is appropriately formed and that no additional damage is done to the surrounding area. The welding lens should also protect your eyes from harmful UV rays, which can cause eye damage over time.

Will this lens work for the eclipse?

There is no 100% certainty, but it is believed that welding lenses may work for the eclipse. They are designed to protect your eyes from harmful UV rays. While it is still unclear whether or not they will be effective, it is a good idea to consult with an eyewear retailer to find out more about the options available.

What size lens do you need for the welding helmets?

The lens size depends on the welding helmet’s make and model. Some of the more popular welding helmets include the MSA Matrix and the PIPE-Pro. Both of these helmets come with various lens sizes, so it is essential to find the right one for your needs.

The MSA Matrix comes with various lens sizes, including a large extent that is perfect for those who wear a large helmet. The PIPE-Pro also comes in multiple sizes, including a large area perfect for those wearing a large welding helmet. Additionally, both helmets come with a lens cleaning kit and a case.

Final Words

Welding is a vital part of many industrial and construction jobs. But, like any other job, there are risks involved. Always wearing a welding helmet and using proper safety gear is essential. In this article, we provide you with five tips on cleaning your welding helmet lens. By following these tips, you’ll be able to keep your helmet in good condition and avoid any accidents while welding.

I am an enthusiastic student of optics, so I may be biased when I say that optics is one of the most critical fields. It doesn’t matter what type of optics you are talking about – optics for astronomy, medicine, engineering, or pleasure – all types are essential.

Table of Contents